-scaled.jpg)

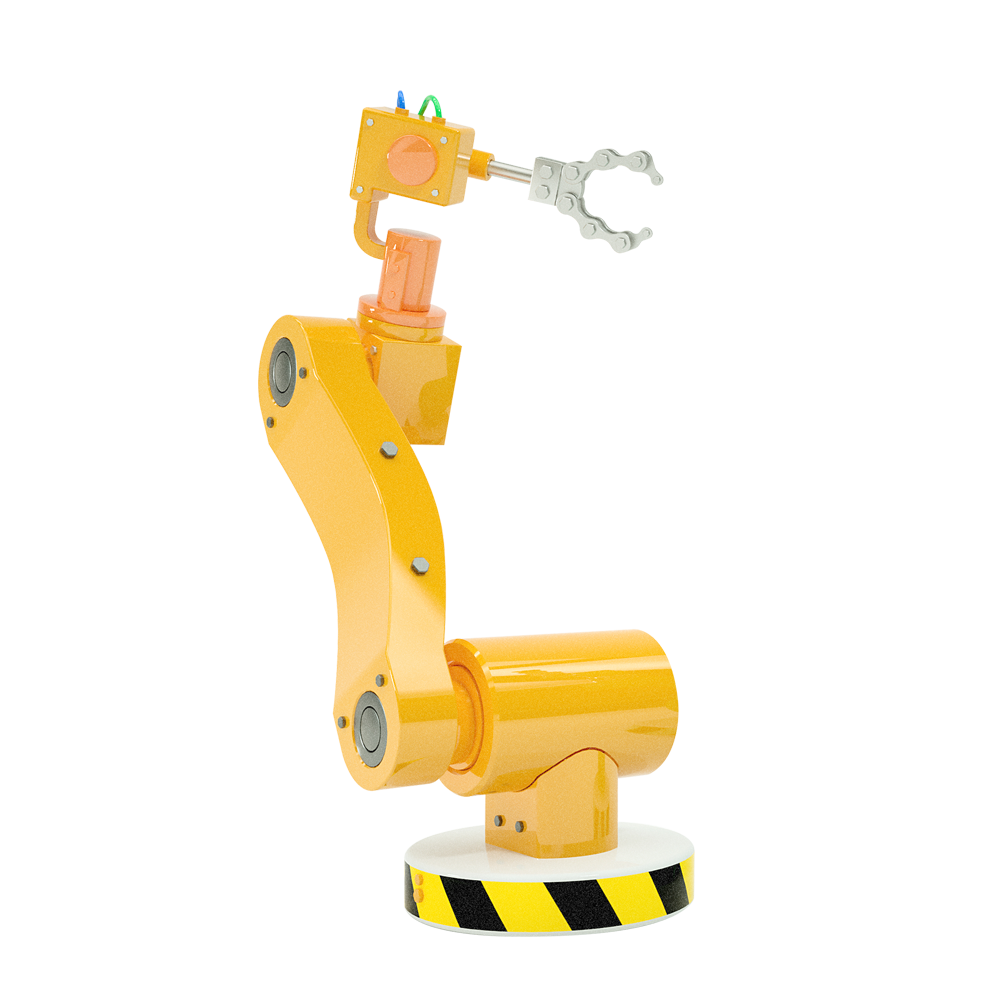

Create the most complex automated systems with high quality parts

Source high-quality robotics parts to accelerate innovation

- Tight tolerances & complex design

- Wide selection of materials

Summary of Industry

The robotics industry relies on a variety of metal and plastic parts to manufacture robots and robotic systems. These parts serve different functions, including structural support, movement mechanisms, sensor integration, and connectivity.

Full Industrial Quality Certifications.

- ISO 9001

- ISO 14001

- ISO 13458

- IATF 16949

- AS 9100

Rigid Quality Control Documentation

- CMM Inspection Report

- Full Dimensional Inspections

- Material Test Reports

- Material Certificates

- Certificates of Conformance

- First Article Inspections

Why the Automotion industry chooses Yaodi?

Get access to cutting-edge capabilities and reliable performance

Our suppliers are chosen based on their expertise, capabilities, and commitment to quality. They have a proven track record of delivering exceptional products and services, placing a strong emphasis on precision, efficiency, and reliability. We work closely with our suppliers to maintain open lines of communication and ensure seamless collaboration throughout the manufacturing process.

Rigid Quality Control in every process

We understand that the quality of the parts we deliver is critical to the success of our customers’ projects. Therefore, we prioritize rigorous quality control measures throughout the entire manufacturing process. From the selection of suppliers to the final inspection of finished products, we adhere to strict quality standards to ensure that only top-notch parts reach our customers.

What parts can Yaodi support?

CNC machining

- For cost-efficient prototypes and production

- 60+ metals & plastics, including 10+ aluminum & 20+ steel

- Lead time from 2 days

3D printing

- 25+ plastics & 35+ colors

- ±0.3% dimensional accuracy with a lower limit down to ±0.15mm

- Lead time from 1 day

-1024x683.jpg)

Sheet metal fabrication

- 6 metals & 9 surface finishes

- Tolerances down to ±0.01mm

- Lead time from 2 days

Injection molding

- Wide range of part complexities and sizes

- 1mm to 1M parts

Gallery